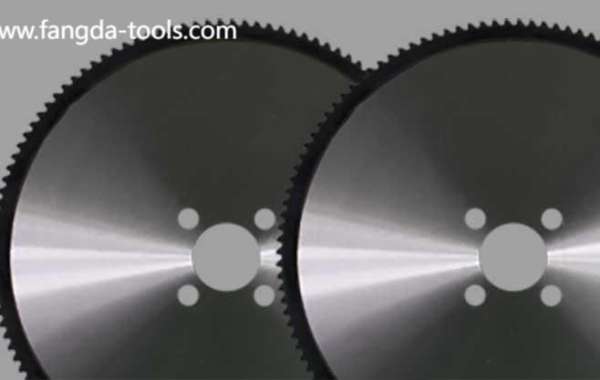

In the pursuit of refined craftsmanship and efficient production, tool choice plays a crucial role. Fangda’s TCT Circular Saw Blade offers a dependable solution for industries that require controlled, smooth, and powerful cutting performance. Built to serve woodworking, aluminum fabrication, and furniture manufacturing, this blade integrates material strength with consistent precision.

The teeth are crafted from tungsten carbide, known for its resistance to high temperatures and prolonged wear. This allows the blade to retain sharpness through repeated cuts, especially under fast-feed operations. The optimized tooth design promotes clean slicing action while reducing the risk of material chipping or surface splintering.

In high-throughput environments, cutting tools must keep pace with production demands. This saw blade’s balanced steel core minimizes vibration, enabling more stable cuts and reducing strain on machines. Its expansion slots manage heat buildup, preserving blade shape during intensive cycles and ensuring safety.

The ability to maintain quality over extended operation sets this blade apart. It reduces the need for frequent blade changes, supporting uninterrupted workflow in saw stations or CNC cutting tables. For operators, this translates into fewer pauses and greater efficiency throughout the cutting process.

Modern workshops are seeking equipment that adapts easily to evolving materials. Whether it’s dense plywood, soft plastics, or aluminum profiles, this blade is suited for various substrates without compromising cut accuracy. Its compatibility with different machines offers additional flexibility across workspaces.

Noise reduction also adds to the user experience. Carefully engineered blade profiles reduce whistling and frictional sound during cutting, helping create a quieter, more focused production atmosphere—an important factor in modern lean manufacturing practices.

For contractors and manufacturers alike, precision translates into reputation. Clean edges and consistent performance reflect the quality behind every finished product. Choosing high-end tools like these ensures fewer reworks, smoother assemblies, and stronger customer satisfaction.

When performance must meet productivity, selecting a high-quality blade becomes a strategic decision. To learn more about durable cutting tools for industrial applications, visit: fangda-tools.com