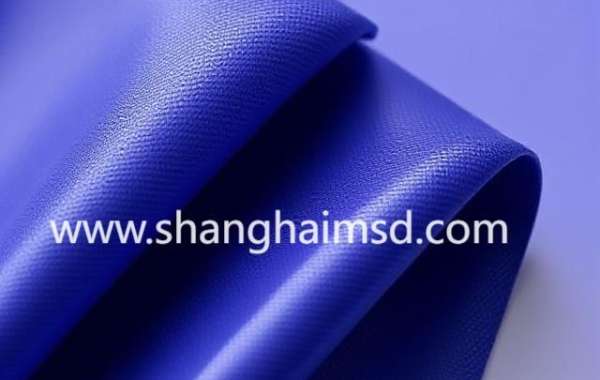

In industrial settings where products must be shielded from environmental stress, chemicals, and mechanical impact, TPU Compound Film has proven itself as a superior protective material. Shanghai MSD International Trade Co. supplies high-performance TPU films that meet the evolving needs of the global packaging and protection industries.

Unlike conventional packaging plastics, TPU Compound Film provides both flexibility and resilience. It is used in a wide range of industrial covers, protective wraps, and technical liners that demand durability under harsh conditions. This includes components for electronics protection, pallet covers, heavy-duty bagging systems, tool pouch laminates, and even flexible ducting materials.

The film’s tensile strength and tear resistance make it particularly suitable for protective sheets that need to be lightweight but robust. It stretches without breaking, conforms to irregular shapes, and resists punctures, offering enhanced product security during transport or storage. TPU also has excellent low-temperature flexibility, allowing it to maintain its integrity even in cold-chain logistics or outdoor industrial settings.

One of the critical benefits in packaging applications is TPU’s resistance to oils, chemicals, and abrasives. Whether used in factories, construction zones, or mechanical environments, the film safeguards against leaks, splashes, and external contaminants. It also withstands repeated bending and folding without developing stress marks or surface fatigue.

Shanghai MSD International Trade Co. supports industrial manufacturers with a wide range of TPU film formulations, including flame-retardant, anti-static, UV-resistant, and colored versions. These features make the material even more adaptable for specialized packaging purposes—such as covering sensitive electrical components or wrapping chemical drums.

In custom applications, TPU films can be easily die-cut, welded, or laminated to other substrates, including fabrics or foam. This flexibility enables the creation of multi-layered protective systems such as gaskets, seals, transport bags, or flexible partitions. Because of its weldability, TPU films provide airtight and watertight bonds without adhesives that may degrade or emit harmful compounds.

From an operational perspective, TPU film also contributes to sustainability. It is often reusable, and its durability reduces the need for replacement. Moreover, many formulations offered by Shanghai MSD are free from halogens and plasticizers, making them a safer and more environmentally responsible option compared to legacy materials like PVC or rubber composites.

Industries that deal with sensitive instruments, heavy tools, or hazardous materials appreciate TPU film’s performance and safety compliance. It helps reduce product damage, improve packaging life cycles, and minimize environmental waste. Whether used as a standalone wrap or integrated into a more complex protective design, the material ensures industrial reliability.To learn more about industrial TPU film solutions, visit: https://www.shanghaimsd.com/ .