In the realm of garment production, Interlining plays a vital role in enhancing fabric stability and overall garment structure. The presence of interlining within clothing layers ensures durability and helps maintain the intended shape, crucial for both casual and formal wear. This hidden component supports the outer fabric, allowing garments to withstand daily wear and environmental stress while offering a polished appearance.

Foundations of Garment Structure

A well-constructed garment depends heavily on internal support layers that provide form and resilience. This reinforcement helps garments maintain their design integrity, preventing unwanted stretching or sagging. Properly engineered support enhances the overall silhouette, providing a sharp, professional finish that elevates the wearer’s confidence and comfort.

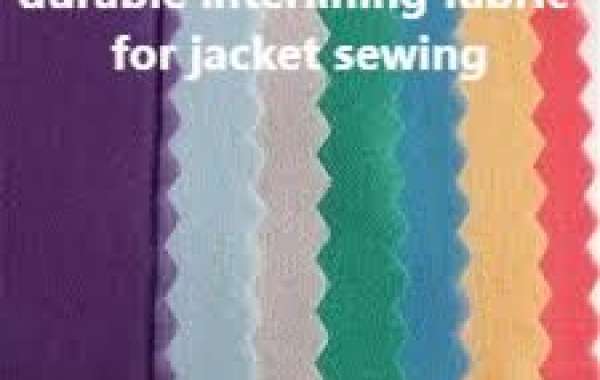

Material Types and Their Importance

Support layers vary in material composition, tailored to specific fabric types and garment requirements. Heat-activated adhesives bond certain internal layers to fabrics, suitable for robust, everyday apparel. Sew-in alternatives are preferred for delicate textiles that may be sensitive to heat. Understanding the unique qualities of these materials allows manufacturers to select the most effective solution for each garment type.

Comfort and Wearability Considerations

Beyond structural benefits, the internal reinforcement layer contributes significantly to the wearer’s comfort. It must integrate seamlessly without adding stiffness or bulkiness, preserving the natural movement of the garment. Achieving the right balance between support and flexibility is essential, especially in clothing designed for extended wear or active use.

Sustainability Trends in Garment Reinforcement

As the fashion industry moves toward sustainability, eco-friendly materials and production methods are gaining traction. Manufacturers are exploring recycled fibers, biodegradable adhesives, and environmentally responsible processes to minimize the ecological impact. These advancements ensure that garments meet modern environmental standards without sacrificing quality or performance.

The Future of Garment Construction Innovation

Technological advancements in textile engineering promise lighter, stronger, and smarter reinforcement solutions. Innovations may soon include adaptive materials responding dynamically to movement or environmental changes. Such developments will continue to shape garment manufacturing, providing enhanced performance while maintaining design excellence.For further insights on garment support materials and their diverse applications, please visit https://www.interlining-factory.com/news/what-is-interlining-types-applications-and-more.html